Bus Natural Gas Engine

This bus natural gas engine makes use of the compressed or liquefied natural gas as fuel to work as the power support especially for the medium and heavy duty vehicles, such as city bus, intercity coach and regional transport truck. It can meet the demands of abovementioned vehicles, like high performance, low pollutant discharge and low noise.

SC9DT Natural Gas Engine

| Model | Unit | EURO III, Euro III/Euro IV/Euro V | |

| SC9DT280Q3 | SC9DT320Q3 | ||

| Type | 6 cylinders, in-line, 4 stroke, water cooling | ||

| Aspiration | TCI | ||

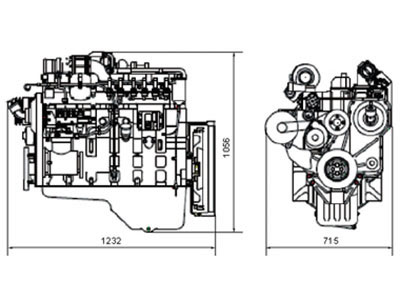

| Bore ×Stroke | mm | 114×144 | |

| Total displacement | L | 8.8 | |

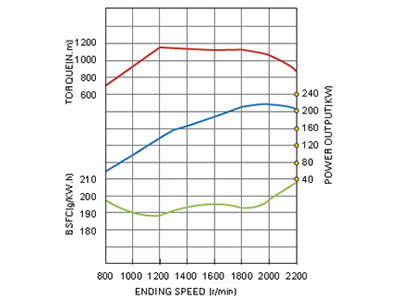

| Rated power/rated speed | kw/r/min | 206/2200 | 235/2200 |

| Min. fuel consumption | g/kw.h | ≤190 | |

| Maximum torque/speed | N.m/r/min | 1120/1300~1400 | 1250/1300~1400 |

| Noise | dB(A) | ≤96 | |

| Weight | kg | 760 | |

| Power range | ps | 280~320 | |

Features

1.Electronic Throttle Valve

The electronic throttle valve is applied to adjust the rotation speed and output power of the bus natural gas engine automatically. When the engine outputs large power at idling, it helps drive the accessories of the air conditioner easily.

2. Gas System

This gas system consists of imported gas apparatuses in mass production with advanced technology and reliable performance. It utilizes the single point injection technology to make sure the fuel is mixed with the air adequately and the fuel in each cylinder burns smoothly and stably.

3. Post Treatment

In the post treatment, this engine adopts the binary oxidation catalytic converter to keep the emission consistent with the Euro IV standard.

4. Self-diagnosis and Calibration

Due to the SAE J1587 communication protocol, it is convenient for the engine to do the fault diagnosis and calibration for the vehicle.

5. Generality of Structural Spare Parts

This bus natural gas engine chooses the essential parts and components that are basically exchangeable with that of the diesel engine of mass production. Therefore, it is very convenient for maintenance and repair.

6. High Energy Ignition System

With excellent adaptability for the changes of the battery voltage, this high energy ignition system makes full use of the ignition energy in the direct ignition way. It improves the fuel efficiency effectively.

7. Close Loop Control of Air Fuel Ratio

The electronically controlled unit is applied in the bus natural gas engine to collect the operating parameters, such as the pressure, temperature of intake manifold and the natural gas, atmosphere conditions, rotary speed, water temperature, etc. It gets the injection volume of the natural gas in accurate control. In respect of the measured value of the UEGO sensor, the air fuel ratio will be corrected in the closed loop.

8. Intake System

Aided with the supercharger working on the intake or exhaust valves, the intake pressure is controlled in the close loop. Moreover, the intake air passing through the inter cooler will decrease the combustion temperature and emission.

English

English Britain

Britain Canada

Canada India

India Français

Français Español

Español Русский

Русский Việt Nam

Việt Nam ประเทศไทย

ประเทศไทย العربية

العربية Português

Português Türkiye

Türkiye فارسی

فارسی