Gas Series Engine

Technical Specifications

SDEC's natural gas series engine is a medium and heavy duty engine fuelled by compressed natural gas (CNG) or liquefied natural gas (LNG). It is used for the supporting power of buses, intercity buses and regional transport vehicles, meeting the high performance, low emission and low noise required by the above mentioned vehicles.

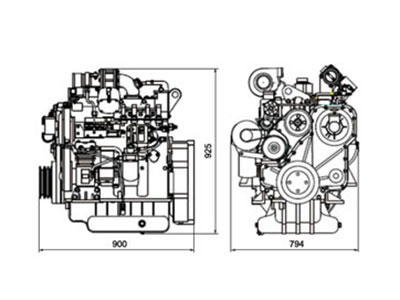

Gas Engine SC5DT

Power Range: 160-180PS

| Model | Unit | EuroIII | EuroIV | ||

| SC5DT160Q3 | SC5DT180Q3 | SC5DT160Q4 | SC5DT180Q4 | ||

| Type | 4 In-line, 4-Stroke, Water-cooling | ||||

| Aspiration | mm×mm | TCI | |||

| Bore×Stroke | L | 114×130 | |||

| Total Displacement | 5.3 | ||||

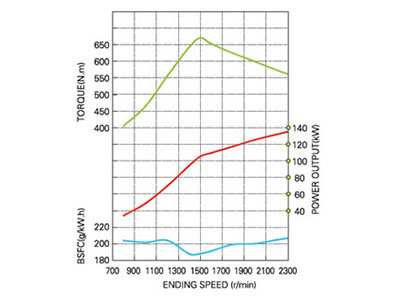

| Rated Power/Rated Speed | kW/r/min | 118/2300 | 132/2300 | 118/2300 | 132/2300 |

| Mini Fuel Consumption | g/Kw.h | ≦220 | |||

| Maximum Torque/Speed | N.m/r/min | 580/1400-1600 | 650/1400-1600 | 580/1400-1600 | 650/1400-1600 |

| Noise | dB(A) | ≦98 | |||

| Overall Dimension | mm | Length: 900 Wide: 794 High: 925 | |||

| Weight | kg | 540 | |||

A binary oxidation catalytic converter is used to ensure the emission meets the Euro IV Standard.

SAE J1587 Communication Protocol is used to make the fault diagnosis and vehicle calibration more convenient.

The rotating speed and output power of the engine are automatically regulated. In the case of idle speed, the engine output power is large, making it easier to drive the air-conditioning accessory.

An imported gas device (in mass production with advanced technology and reliable operation) is used to realize single-point injection before the throttle valve, ensuring adequate mixing of fuel and air as well as stable and smooth combustion of each cylinder.

The high-energy ignition module has strong adaptability to changes in battery voltage. The direct ignition method is applied to fully utilize the ignition energy for improving combustion efficiency.

Engine operational parameters collected by electrically controlled unit; pressure and temperature of inlet manifold and natural gas, atmospheric condition, rotating speed, water temperature, etc. accurately control the injection volume of natural gas, and the air-fuel ratio is corrected in close loop based on the measured values from wide-range oxygen sensor.

The basic spare parts are versatile for mass-produced diesel engines, allowing for convenient maintenance.

The inlet pressure is controlled in close loop by the pressurizing exhaust valve. The inlet air is cooled in the process and the combustion temperature and emission is lowered.

English

English Britain

Britain Canada

Canada India

India Français

Français Español

Español Русский

Русский Việt Nam

Việt Nam ประเทศไทย

ประเทศไทย العربية

العربية Português

Português Türkiye

Türkiye فارسی

فارسی