D Series Diesel Engine for Generating Sets

The D series engine is the brainchild jointly designed by SDEC and AVL. It is developed regarding the Chinese oil products and users' application habits. It is the most recently designed and most technologically advanced engine among the current domestic mature engines as well as one of the mainstream matching powers for domestic engineering machineries, with sales amounting to more than 600,000 pieces. The main models of the Euro II D series engine are D4114, D6114 and D9.

Diesel Engine SC9DF

| Model | Unit | EURO Ⅲ | EURO Ⅳ | ||||

|

SC9DF260

Q3 |

SC9DF320

Q3 |

SC9DF375

Q3s |

SC9DF260

Q4 |

SC9DF320

Q4 |

SC9DF375

Q4 |

||

| Engine Type |

|

Direct Injection, Straight-Line, Water-Cooling Cylinder Liner, Six-In-Line, Four-Stroke, Water Cooling | |||||

| Intake Mode |

|

Mechanical Fuel Pump, Turbocharging (Charge Inter-Cooling) | |||||

| Cylinder Bore ×Stroke | mm×mm | 114×144 | |||||

| Total Displacement | L | 8.8 | |||||

| Compression Ratio |

|

18:01 | |||||

| Standard Power/Rated Rotate Speed | kW/r/min | 192/2200 | 235/2200 | 275/2200 | 192/2200 | 235/2200 | 275/2200 |

| Fuel Consumption at Standard Working Condition | g/kW.H | ≤215 | |||||

| Max. Torque/Rotate Speed | N.m/r/min | 1100/1400 | 1250/1400 | 1500/1400 | 1100/1400 | 1250/1400 | 1500/1400 |

| Noise | db(A) | ≤98 | |||||

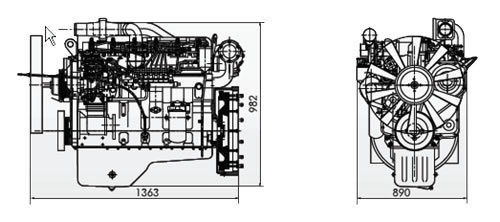

| Overall Dimensions | mm | 1363 (Length) ×890(Width) × 982 (Height) | |||||

| Weight | kg | 770 | |||||

SC9DF Product Features

SC9DF engine is an electronically controlled four-valve 9L product developed

on the basis of D series by SDEC with consideration of the world's heavy-duty

diesel engine development trend and the Chinese working features. Besides

some basic performance of SDEC's electronically controlled products, it

has the following features:

Four-valve structural arrangement, which improves intake efficiency and has better fuel economy.

Electronically controlled high-pressure shared-rail fuel system, which has injection pressure up to 160Bar, better atomizing effect and more sufficient combustion.

Integrated design of engine oil filtering system. The filter element design gets rid of the integral iron sheet case filter element. The user can change the paper filter element directly, greatly reducing maintenance costs and it is more environmentally friendly.

Exhaust braking technology and engine in-cylinder braking. The compression energy produced by engine inertia is used for braking. The peak braking power is up to 160kW. The complete vehicle fuel economy has been improved and the complete vehicle safety has been greatly enhanced.

The D series electronic-controlled diesel engine is an electronically controlled high-pressure shared-rail engine developed based on the original D series products on which SDEC has made electronically controlled layout in cooperation with famous companies including Denso since 2002. In 2005 SDEC's SC8DK electronically controlled engine passed the expert approval organized by Shanghai Municipal Economic Commission and has been rated as ‘a new generation of energy-efficient and environmentally friendly engines with proprietary intellectual property rights, reaching the international level of this century among similar products and at the leading domestic level. Products like SC5DK and SC9DK were also developed successfully. In 2006, SDEC joined U.S. Southwest Research Institute (SWRI) to develop the SC9DF electronically controlled Euro III/IV engine, upgrading the power of electronically controlled products to 375 horsepower. The main models of Euro III/IV D series electronic-controlled engines are SC5DK, SC8DK, SC9DK and SC9DF.

Features of Euro II D Series Diesel Engines

High Reliability

The overall structure is designed with multi-functional integration of

parts. The structure is simple, with parts 25% less than general diesel

engines, reducing fault troubles and increasing product reliability.

Good Use Efficiency

Under the equivalent use conditions, it is more fuel-efficient, equipped

exclusively with the core fuel-efficient technology.

Extensive Application

The 114 series products are used for loaders, bulldozers, excavators,

truck cranes, road rollers, pavers, land levelers, tractors and milling

machines, etc.

Easy Maintenance and Care

With sales amounting to 600,000 and nationwide maintenance networks and

spare parts storage, D series products are very easy for maintenance and

care.

Features of Euro III/IV D Series Diesel Engines

Complete Functions

SDEC's Euro III engine is equipped with an ECU system, upgrading the overall vehicle.

Electronically controlled exhaust braking system: turn on and turn off the exhaust braking system according to the engine working condition and the driver's intention.

Whole vehicle cruise functetw_productsion: cruise function on expressway relieves the driver's fatigue and adds driving comfort.

Maximum speed protection: limit highest vehicle speed, protects the engine and the complete vehicle, and improves complete vehicle service life.

Idling adjustment: the diesel engine changes the idling state or accelerates engine for warm-up according to the engine condition and changes the engine speed according to condition of accessories such as the complete vehicle air-conditioning.

The engine's electronically controlled system is capable of self-diagnosis, and can issue an alarm through the fault indicating lamp and display the fault category. In case of major failure, the engine can carry out protective action.

High Reliability

It features mature engine body technology. The electronically controlled

engine is developed based on Euro II, with basically the same parts (body,

cylinder cover, crank axle, piston and lever, etc.). It is used in equipment

like trucks, passenger cars, engineering machineries, engine sets, etc.

It has been strictly tested in very harsh environments, for example, plateau,

extremely hot, cold and dusty environments. It uses the most mature electronically

controlled high-pressure shared-rail system in the world and its key parts

are from world famous brands. Under proper use conditions, its overhaul

period is up to 800,000 km.

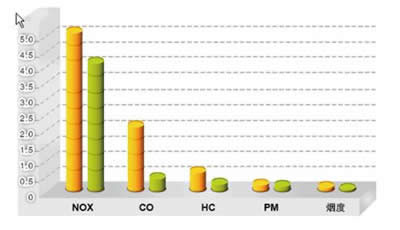

Fuel Saving

The combustion system of electronically controlled engine has been fully

optimized, making full use of every drop of oil. Characteristics minimum

fuel consumption is 193g/KW.h, and rated point fuel consumption is less

than 215g/KW.h. Fuel consumption of the complete vehicle has been further

reduced.

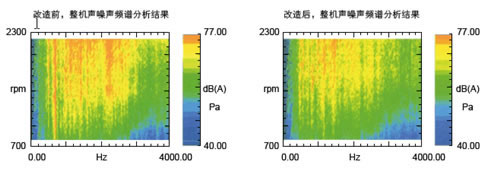

Low Noise

By optimizing the injection rate, delaying injection timing and adjusting

injection pressure, the combustion noise of the engine has been reduced

by 2~3 decibel, the overall engine noise is lower than 98 decibel, and

the overall noise of the passenger car when accelerating drops to 82 decibel.

The electronically controlled diesel engine uses pre-injection technology

and oil injection consistent calibration, which significantly improves

the combustion condition of diesel engine and the consistence of combustion

in all cylinders, and reduces the engine noise.

English

English Britain

Britain Canada

Canada India

India Français

Français Español

Español Русский

Русский Việt Nam

Việt Nam ประเทศไทย

ประเทศไทย العربية

العربية Português

Português Türkiye

Türkiye فارسی

فارسی